Excess stock is a pain point for many small businesses, as it eats into hard-earned profits through slow-moving and obsolete items. In principle, excess stock or excess inventory is the byproduct of incorrect decisions made at various stages of the business. Entrepreneurs often struggle to meet customer expectations while managing inventory effectively. Frequently, the products they keep in stock remain unsold, while items that are in demand are out of stock. This dilemma is a fundamental issue in all types of retailing and stocking businesses worldwide.

However, what if I told you there are simple and effective solutions available, based on the principles of the theory of constraints, that can help you overcome this problem?

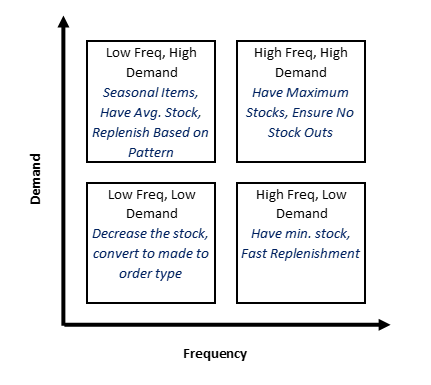

To start, it’s important to identify a suitable inventory model for the business by categorizing products based on their selling nature. This involves dividing products into different categories based on their frequency of sale and demand.

Frequency of sale refers to the number of times items are requested from the stock or sold. [It’s important to note that if items are not in stock, many customers may seek them elsewhere, so the frequency of stock outs also be considered.]

Demand for a product can be defined as the volume of requirement for the product. At times, the volume of demand may be high, leading to rapid depletion of stock, while at other times, the stock may move slowly with fewer sales.

Categorize the products into the four types as explained in the below graph. Allocate the products into different types for taking decisions. The bucket types are

- Low Frequency, High Demand

- Low Frequency, Low Demand

- High Frequency, High Demand

- High Frequency, Low Demand

High Frequency, High Demand

This category of products is normally referred to as top sellers. These products are sold almost every day, with volumes ranging from low to high. They are the breadwinners of the business. Any stock-out situation can lead to a severe drop in sales and pose a risk to the business’s reputation.

Inventory Model: These products need to be stocked at 100% capacity at all times, so significant investment should be made to keep the business operational. Stock levels should be calculated based on daily demand and lead time for replenishment. Higher service levels should be considered for these items, allowing inventory to be kept at maximum levels. The maximum limit varies from business to business based on its lifespan, but maintaining stock at the maximum demand level is expected here.

Challenges: Having a wide range of product varieties in this category poses a challenge because it’s difficult to predict which category will sell the most. If it’s not a standard commercial item, factors such as the color, design changes, and frequent shifts in market tastes can affect sales. To prevent excess inventory of these items, stock levels should be carefully determined based on the stage of the product’s life cycle (introduction, growth, maturity, decline).

Low Frequency, High Demand

This category items are noted as seasonal items considering the frequency and high demand. People would buy some of the items for a specific time but in higher volume. It may be linked weather, climate, festival, political change, traditions etc.

Inventory model: For these products, prior seasonal preparation is necessary. Based on the sales of the last cycle (which could be a year or a month), the average sales of these products should be estimated. Considering the variety of products, it is necessary to purchase only the average level of inventory before the season begins. Once the season starts, the sales pattern can be easily determined from the actual point of sale. This pattern should be understood to adjust the stock level accordingly. The overall stock level should be constantly updated (either by reducing or increasing) based on the sales trend during the season.

Challenges: The initial stock levels should be carefully determined based on the stage of the product’s life cycle (introduction, growth, maturity, decline). As the sales trend from the last year does not guarantee the current year’s sales, especially if the product is in the maturity or declining stage. Avoid purchasing seasonal quantities in full lots to obtain discounts from your supplier, as this could lead to selling those items at a discounted price.

High Frequency, Low Demand

This category of products has minimal consumption with a high frequency of selling. People usually do not buy in higher volumes due to the nature of consumption being less (such as cosmetics), being unable to store the product for a long time (like ice creams), or preferring very fresh produce (such as vegetables) from the market.

Inventory Model: For these kinds of products, it is advised to maintain a minimum level of stock. This will allow for more variety while keeping inventory costs the same. Sold products can be replenished faster from the supplier’s warehouse through the distribution channel or directly from the producer. The stock level can be determined based on the maximum lead time for replenishment from the supplier. In some cases, opting for a supplier with a shorter lead time may be necessary, even if it means higher costs.

Challenges: You might be tempted to purchase these items in larger quantities at lower costs due to discounts. However, it’s important not to fall into the fallacy of buying more just because of discounts, as this could erode your profits in the long term. It’s advisable to only purchase the minimum amount, even if it means paying a slightly higher cost. If the supplier doesn’t agree, explain to them that the quantity of purchases will remain consistent in the long term, but the frequency will be higher than normal.

Low Frequency, Low Demand

This category of products is typically referred to as slow-moving items. These products are the primary cause of most obsolete inventory in businesses. The decision to keep them in stock mainly arises because we cannot avoid these products as they are crucial to satisfying customer demand. However, the demand for these items is very low and inconsistent, making it challenging to estimate accurately due to its pure randomness.

Inventory Model: To begin with, the stock level should be minimized to the minimum required at any given point in time. Rather than holding onto stock for extended periods, one should consider the possibility of obtaining items from the supplier as needed, even if it means paying a higher cost. In a manufacturing environment, this is referred to as a made-to-order type rather than a make-to-stock type. The profit margin for these products should be relatively higher than others, as we anticipate slow-moving sales.

Challenges: If maintaining minimum inventory is not feasible due to supplier minimum order quantities, it requires proper engineering for better solutions rather than resorting to the traditional approach. Sometimes, importing materials can result in longer lead times, leading to slow-moving stock due to excess purchases. If local purchasing is not possible for imported items, frequent replenishment, even at a higher cost, saves money in the long term compared to letting them become obsolete.

Categorizing the products into the above model will help us define the suitable inventory model for the small business. Reviewing these inventory methods at intervals is also necessary as customer preferences change over time.

Leave a Reply